400 099 7576

400 099 7576Key points in sample preparation:

1、Cutting

Cemented carbide has high hardness and some blades are small in size. High-power precision cutting machines and diamond cutting blades are generally used for cutting. Cutting requires a low feed rate and stable clamping to prevent sample cracking caused by cutting.

SmartCut-10 manual precision cutting machine Resin diamond cutting blade cutting carbide disc

2、Mounting

Carbide specimens usually need to be ground and polished after mounting. For mounting, a powerful hydraulic hot mounting machine (above 20Mpa) with an independent hydraulic station should be used, and a hot mounting resin with high hardness and high edge retention performance should be used for mounting protection. If cold mounting must be used under certain special conditions, it is also necessary to add reinforcing ceramic or glass powder to the resin to increase the hardness of the resin.

Penetration-20 Automatic Hot Mounting Machine MW002 Edge Protection Hot Mounting Resin

3、Grinding & Polishing

The high hardness of cemented carbide determines that sandpaper is powerless against it. Here we recommend Truer's patented diamond grinding disc. When the amount of material removed by grinding is large, GD-Dia80# or 220# can be used with DS001 polycrystalline diamond suspension or sharpening rod as the first step of grinding. When the cutting surface is smooth and flat and no material needs to be removed, GD-Dia500# or GD-Sof fine grinding disc with DS001 polycrystalline diamond suspension can be selected as the first step of fine grinding.

GD Diamond Magnetic Grinding Disc DS001 Polycrystalline Diamond Suspension

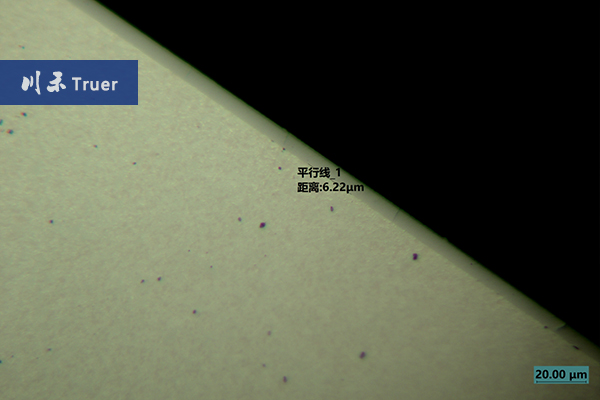

Hard materials are usually easy to polish. When there are multiple layers of wear-resistant coatings on the surface of cemented carbide materials, OS001-JP 0.05 micron oxide polishing can be added to increase the contrast between the coating and the substrate and better distinguish the coating.

Smoothneer-6 Metallographic Automatic Grinding and Polishing Machine OS001-JP Alumina Polishing Liquid

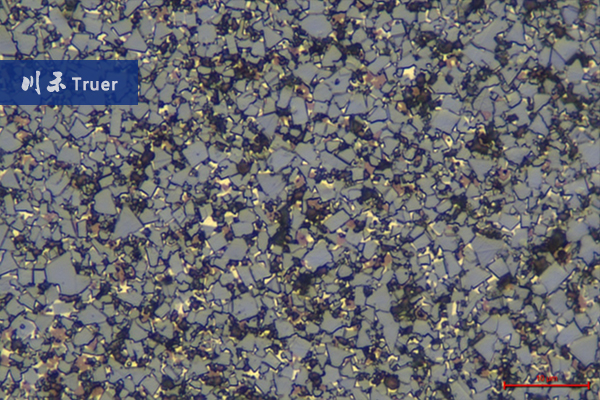

4、Etching

The sample was etched using the corrosion solution of ISO-4499 standard, which was a mixture of 20% potassium hydroxide solution and 20% potassium ferrocyanide solution in a ratio of 1:1.

Grinding and polishing:

.png)

The above recommended parameters are taken from: Preparation method of Ф30 mm cemented carbide sample with Ф300 mm working disc on automatic grinding and polishing machine Smoothneer-6.

Surface coated carbide

WC-CO-TI alloy

*The above pictures may not be reproduced without permission, otherwise legal liability will be pursued.

TOP