400 099 7576

400 099 7576 2020-11-02

2020-11-02

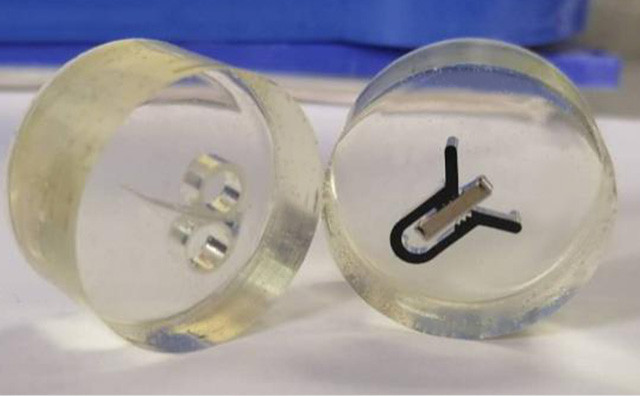

Inlaying is actually to fill and cover the cut sample with liquid resin in a fixed film cavity, and demold it after the liquid resin is solidified to form a standard-shaped inlaid sample.

.jpg)

According to the operating temperature, there are two types of cold mounting and hot mounting. Cold mounting is actually the process of using a resin that is liquid at room temperature, adding a curing agent, and then pouring it into a plastic mold, and then cross-linking and curing; cold mounting is mostly used for some heat-sensitive and pressure-sensitive samples. Hot mounting is to use resin particles that are solid at room temperature, fill them into the mold, heat them to a liquid state, tightly wrap the sample after pressurization, and demold them after curing. Hot mounting is mostly used for heat-resistant and pressure-resistant solid materials.

For heat-sensitive materials such as circuit boards, plastics or organic matter, as well as pressure-sensitive samples such as silk materials, porous materials, and coating materials, cold mounting is used to prepare samples. Add a curing agent to the liquid resin, pour it into a silicone or other plastic mold, and demold it after curing. Therefore, cold mounting can be completed without equipment or simple vacuum devices.

The curing time of cold mounting resins varies, and the shrinkage and bubble volume vary. In addition, the hardness after curing is also different. Pay special attention when choosing cold mounting resins. Cold mounting resins are generally divided into the following three categories according to their curing characteristics. Let's take the industry-leading products of Shanghai Truer Company as an example:

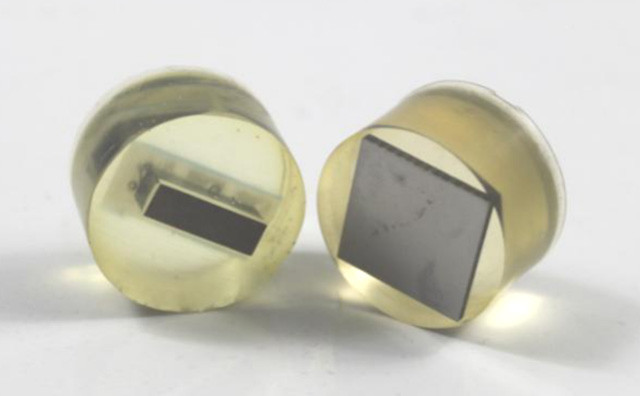

1. High-transparency epoxy:This is a group of epoxy resins that cure relatively gently, achieving more than 80% cure within 2 hours. Fewer bubbles are generated during the curing process, and the sample can achieve excellent transparency without negative pressure equipment, which is particularly suitable for mounting with high visibility requirements such as circuit boards. The curing shrinkage is small and the hardness is high, which is very suitable for samples with key observation requirements on the surface or coating.

2. Flash-curing epoxy:If you are concerned about the mounting time, you can use flash-curing epoxy resin, which can be demolded within 20 minutes. The curing reaction is slightly intense, forming a small amount of bubbles and accompanied by a small amount of heat and temperature rise.

3. High-hardness acrylic:Acrylic resin can be cured quickly within 10 minutes, with low ambient temperature, and the sample has high hardness, but low transparency. Due to the strong odor of acrylic resin, it is recommended to operate in a fume hood.

For porous materials, vacuum negative pressure devices should be used to achieve better penetration effects; mounting in pressure vessels can also suppress bubbles and further improve sample transparency. In addition, cold mounting resins also have special extended products, such as conductive cold mounting materials.

Overall, the selection of cold mounting resins is closely related to specific applications, and correct selection is very important. When encountering specific cases, it is best to consult professionals or even entrust analysis.

All microscopic analyses are the accumulation and crystallization of countless details, and the same is true for metallographic analysis. Even the most inconspicuous defective materials will cause observation defects and misleading. Industry practitioners must be in awe and pursue perfection.

Shanghai Truer Company has been deeply involved in the metallographic testing industry for decades and has long practiced the concept of exquisite metallography. It is a leading metallographic solution provider in China. Truer takes international giants as benchmarks, faces difficulties, concentrates on research, overcomes key equipment and consumables that restrict the development of the industry, and creates a complete metallographic industry chain integrating equipment, consumables and sample preparation training; the company is equipped with a cutting-edge metallographic laboratory and has a team of highly qualified experts. For more than ten years, it has provided metallographic analysis and sample preparation training services to thousands of customers, and provides customized metallographic laboratory solutions.

If you have any metallographic questions, you can get in touch with them to get the information you want.

TOP